What Size Cotton Wick Is Used For Beeswax Votives

by Petra Ahnert

Ahhhh… Fall. This is the time of year that we finally get around to transforming our cappings into beautiful yellow blocks of wax. It is also the time that people offset ordering candles again. Time to get decorated making more candles.

So, what makes a great candle and how is information technology achieved? Beeswax candles are more than than wax and a cotton string. They are a symbiotic human relationship betwixt air, wax, and wick. Since the most challenging candle to get correct is the pillar candle, I volition focus most of this commodity on the components of making a great pillar candle. In my opinion, the perfect pillar candle will create a fire pool that extends out most of the diameter of the candle, but non all the way. The flame is nice and vivid with no smoke trails and the candle burns down all the way to the bottom without looking ugly and misshapen. The latter is actually hard to achieve with taller candles so, although I make them, I adopt the pocket-size and medium sized candles for personal use.

I will first with wicks… Big sigh… This necessary part of the candle seems similar it would exist an easy thing, only honestly, although information technology can exist maddening to effigy out, I tin can't stress enough how important this is to the overall quality of the candle. When a candle is lit, a serial of events take place. First the match lights the wick and the wick itself starts to burn. The flame then starts to melt the wax. The wick acts as a pipeline that carries the melted wax in the form of a vapor to the flame via capillary action. Some wicks let lots of fuel to menses quickly through a big pipe, while other wicks pump fuel more slowly through a smaller pipe. If you give the flame besides much or likewise niggling fuel, information technology will fire poorly, or sputter out. The balance of fuel and flow needs to be just right.

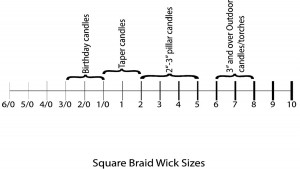

Square Braid Wick Sizes – Wick graphic: Although this is non completely correct in terms of actual diameter of wicking, information technology gives an overall picture of relative sizes, usually available wick sizes and the range of uses.

The classification of square braid cotton wicking refers to the number of bundles, the ply of the wick, and how tightly it is braided. The six/0 to 1/0 range of wicks, are synthetic a bit differently than the larger wicks, but all of them are square which helps to channel the wax fumes up to the flame. It is important to go on your wicks well labeled and separated since like sizes await identical. Often the just divergence is the tightness of the braiding.

The design and classification of this wicking is, I believe somewhat unique to the U.S. Apparently wicking produced and sold in other parts of the world utilize a different grading system and are not the aforementioned. The fact that what we accept here in the US isn't universal is something I discovered after my book was published and I was contacted by European editors that needed conversion factors for the wicking I recommended in my volume.

Square Braid wick forms a carbon cap on the superlative of the wick. The carbon cap radiates heat outward from the flame which helps cook wax which is further abroad from the flame. The wick also bends slightly as it burns which minimizes carbon build-up and makes for a cleaner called-for candle.

The oxygen seems like information technology would be the piece of cake part- either the flame gets oxygen or information technology doesn't. Merely the blazon of the candle and the environs that the candle is burned in play a role in how much oxygen the flame receives. I have institute that the more open up to air the flame is, the better the candle burned. And so taper candles are perfectly gear up for this. Pillars and votive candles, on the other mitt typically outset off called-for beautifully, simply as they burn down wax and the flame travels down into the candle, the flame oftentimes has problems. Either the flame tunnels down the middle of the candle melting very piddling wax and starving the flame of oxygen or the flame melts too much of the wax and flame is flooded and goes out.

#2/0 on the left and #2 on the right. As you can see, the actual bore is about the same, bu the number of threads and the configuration of the thread clusters that make up the wicks are unlike.

So how does i ensure that the candle flame gets the oxygen it needs? Look at the burn pool. The width of the tunnel created by the fire pool is usually determined with the initial burning of the candle. The burn pool, which is the extent of melted wax, establishes the ultimate bore of useable wax that the candle volition e'er use in subsequent burnings. The solid wax remaining around the outside of the burn pool will help the candle to retain its shape. For this reason, I always tell my customers that beeswax candles are intended to be burned all evening, not simply a couple minutes and so extinguished. The combination of proper called-for protocol and correct wick size should ensure that the burn pool reaches the desired width.

The blocks above, show the top and bottom of a wax block that I bought. From the superlative, it looks reasonably clean, but on the lesser, quite a fleck of beloved tin can be seen. This block will take some time and work before it can be used.

The last role of the candle trio is the beeswax itself. I personally detest to render wax, so I let my Karl handle the "heavy lifting" of rendering the cappings into big blocks of wax. I am not going to go into the rendering process here, since the procedure is often automatic in larger operations. The wax that Karl renders out is really pretty clean, but since my candle business organization has outgrown what our hives tin produce, I besides purchase wax off another beekeeper in the area. His wax varies from relatively clean to blocks with rivers of honey buried within.

For things like candles, specially pillar candles, the residual honey in the wax causes the wax to burn down unevenly and to clog the wick. Even though a wax may "look" clean, it may notwithstanding have beloved in it.

The best style to get the last of the honey out of the wax is to allow information technology to clarify in a heated double boiler or wax tank. Admittedly, this job is easier to accomplish with the wax tank than a double boiler, since the wax needs to stay liquid for quite a while until all the dearest has settled to the bottom. I usually let mine settle for a couple days. The best way to tell if it is washed is by checking the clarity of the wax. When it is outset melted, it has murkiness to it. Every bit it settles, it starts to analyze. When the wax is articulate, filter the wax through a clean slice of felt cloth and mold into useable portions. I ordinarily do a diverseness of different sizes, so that I have the right size for whatsoever I am making. The resulting wax is still yellow and still has the signature honey-like scent, although the filtering may have lightened upwardly the wax a lilliputian bit.

The dark spots are flecks of caramelized honey. Likewise being unsightly, these are what ultimately can clog the wick, and ultimately go along the wax from reaching the flame.

The chart gives some general guidelines for wick sizes, simply in order to ensure that the correct wick size is used, a fire test needs to exist performed. Really, the odds of getting it right on the first try is pretty rare, and then this exam probably needs to be performed multiple times until the right wick size is found.

The Right Size Wick

Utilise the post-obit test to determine the proper wick size and calibration up or downwards as needed.

Basic Burn Test

ane. Trim the wick to a length of ¼" (vi mm). If you are testing more than i wick, make certain the candles are conspicuously labeled.

two. Place the test candles on a clean, flat, estrus-resistant surface virtually 3" to 6" (vii.5 cm to 15 cm) apart. Be sure to select a draft-costless spot that is in full view of your workspace. Exercise not leave lit candles unattended.

iii. Light the candles and tape the time. It is disquisitional to proceed an middle on the candles while they are burning, specially when testing new wicks.

iv. If testing colonnade candles, let them to burn for two hours then record the details of the melt puddle and wick advent. Ideally the melt puddle volition achieve the desired diameter by this point. If it hasn't, the wick is most probable too small. Note any soot or mushrooming on the wick.

five. Allow the candle to burn for another four hours and record the details of the cook puddle and wick once again before gently blowing out the flame. At this bespeak the melt puddle of a well-wicked candle will have achieved the desired diameter and should be approximately ½" (1.iii cm) deep.

If the wick is mushrooming, the candle is sooting, or the melt pool is substantially deeper than ½" (one.3 cm), the wick is nigh likely too large.

half-dozen. Allow the candle to cool for at least five hours and repeat steps 4, v, and six until the candle is completely burned. The quality of burn will about e'er modify during the entire burning of the candle. Burn the unabridged candle earlier deciding on a wick.

Wax from different batches tin vary a chip not merely in color, simply likewise in beliefs. One time the right wick size is adamant, test subsequent batches of wax to make sure that the candle still burns the fashion it should and if not, brand the appropriate changes to the wick size.

So now, we tin can brand some candles…

Petra Ahnert is a specialty candle designer living in the Milwaukee area, and is the writer of Beeswax Alchemy.

What Size Cotton Wick Is Used For Beeswax Votives,

Source: https://www.beeculture.com/the-right-size-wick/

Posted by: modzelewskiwhie1962.blogspot.com

0 Response to "What Size Cotton Wick Is Used For Beeswax Votives"

Post a Comment